uniaxial compression test of plastic cylindrical specimen|unconfined compression test data sheet : Brand manufacturer MECH 2120 Mechanics of Materials Laboratory Lab Assignment # 3: Uniaxial Compression Test of plastic cylindrical specimen Safety First! Ignoring Safety Precautions will be penalized. Aim: 1. Apply ASTM-D695 Standard on test .

Grupos de Telegram LGBT - Grupos de Telegram. Povo Animado 🌸. Vitin. LGBT ENTRAR NO GRUPO. PrivateG FREE. Andrei. LGBT ENTRAR NO GRUPO. Moy Apshe bloc. .

{plog:ftitle_list}

Resultado da Barulho Do Foguete. Written by Fausto Carvalho / Henrique Moura / Henrique Tranquero / Tunico. Key: G#m. D#m. Em. Fm. F#m (one step .

In this paper, the typical uniaxial compression test of a cylindrical specimen has been modeled using the finite element method. Ideal cases for compression testing have been developed using only the specimen model under load and displacement-controlled test .Abstract In this paper, the typical uniaxial compression test of a cylindrical spec .

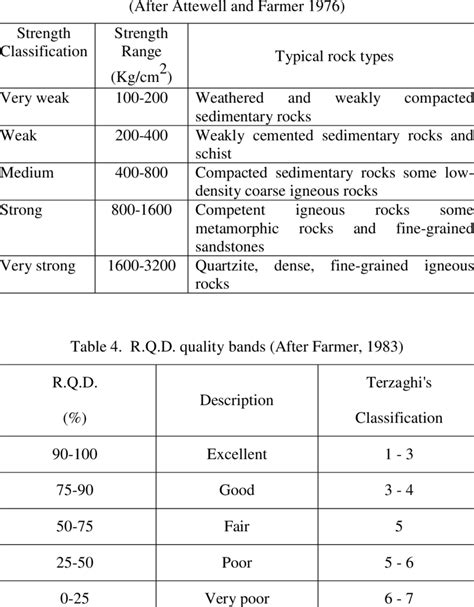

Two methods for uniaxial compression testing were investigated and compared using polypropylene as a model material. An overview of various parameters affecting . For example, it is quite hard to prepare standard cylindrical rock specimens in weak . . rocks for the uniaxial compression test should be greater than 75 mm to obtain a stable UCS.Axial loading of cylindrical core specimen σσσσu = Max. Force/(πππd2/4) 3 Rock Core Specimens. 4 Uniaxial Compression Test GCTS Device ARA Setup at Tyndall AFB, Florida. 5 Uniaxial Compression Test Specimens from drill cores are prepared by cutting them to the specified length and are thereafter grinded and measured. There are

MECH 2120 Mechanics of Materials Laboratory Lab Assignment # 3: Uniaxial Compression Test of plastic cylindrical specimen Safety First! Ignoring Safety Precautions will be penalized. Aim: 1. Apply ASTM-D695 Standard on test . Conventional methods for studying the plastic behavior of materials involve uniaxial tension and uniaxial compression. However, in the metal rolling process, the deformation zone undergoes a complex loading of multidirectional compression and shear. Characterizing the corresponding plastic evolution process online poses challenges, and the .During the plastic deformation portion of a uniaxial compression test, two cylindrical specimens first maintain its cylindrical shape (decreasing in length and increasing in diameter), then: a. Specimen 1 transitions into barreling (the specimen attains a barrel shape) and the breaks. b. Specimen 2 breaks without barreling.Important information is provided for specimen preparation, to ensure that the machining process and the subsequent specimen preparation do not influence the material, since this could in turn affect the results of the tensile test.. There can be a wide range of shapes for tensile specimens. ASTM E8/ASTM E8M lists standard flat specimens for sheet metals and thin sheet metals, for .

Cylindrical core samples of Cobourg limestone were drilled out of cubic limestone blocks using a 3″ diameter diamond core bit. The samples were then produced to meet the standards set out by ASTM D4543 for uniaxial compression testing.By utilizing FOS to measure the full-field strain response of Cobourg limestone specimens subjected to uniaxial stress, . 2 Abstract This laboratory experiment is designed for students to perform uniaxial compression tests on cylindrical specimens of plexiglass (acrylic) and polyvinyl chloride (PVC). The Instron Universal Testing Machine was used to perform the experiment and the BlueHill software was used to record the data while controlling the machine. This experiment followed .

Uniaxial Compression Test of plastic cylindrical specimen Elezer Habtewold Mechanical Engineering Student at UT Dallas Richardson, Texas [email protected] Abstract — A compression test determines behavior of materials under crushing loads. The specimen is compressed and deformation at various loads is recorded. Compressive stress . Proper alignment of test specimens is vital to avoid bending forces, particularly detrimental to brittle materials. Strain measurements employ extensometers or strain gauges, with modern digital systems and analog machines meeting and exceeding accuracy standards for metal tensile testing. Uniaxial tension test procedure: Materials required:Abstract In this lab we performed uniaxial compression tests on cylindrical specimens of acrylic and nylon. These tests were performed with an Instron Universal testing machine and Bluehill software to control the machine and collect required data. We used the ASTM D695-15 standards to carry out the experiment. This experiment gave the students practical exposure .

Uniaxial compression tests require a careful test set-up and strict specimen preparation. Requirements for specimen preparation and tes ting are discussed in ASTM D-2938-86 and in the ISRM suggested methods (Bieniawski and Bernede, 1979). End effects can also be important especially if the load platens are not chosen accordingly. End platens . The principle of UCS involves placing cylindrical samples or prepared drill cores under axial loading until the failure moment in a uniaxial compression test (UCT) device. Figure 1 illustrates a .

While uniaxial tests can be performed on cubic, prismatic and/or cylindrical specimens, to eliminate potential size and/or shape effect discrepancies, cylindrical specimens of the same dimensions .They affect both the elastic and plastic behavior of the material being tested, and can dramatically change the material’s response to the applied load. . The compressive strength of PP typically falls in the range of 35-45 MPa. In a . Characterization of friction stir consolidated recycled billet by uniaxial compression tests with miniaturized cylindrical specimen LATIF Abdul, INGARAO Giuseppe, FRATINI Livan, HETZ Peter, MERKLEIN Marion . P. Hetz, M. Kraus, M. Merklein, Characterization of sheet metal components by using an upsetting test with miniaturized .

uniaxial vs unconfined compressive strength

The uniaxial monotonic compression test is the first type of test within this program. The specimens were produced in the Road and Railway Research Laboratory by means of a gyrator. Cylindrical specimens of 100 mm high . The uniaxial compression mechanical model of a typical composite rock specimen with a horizontal interlayer is shown in Fig. 4. where A is the main rock mass; B is the weak interlayer; h 1, h, and .

testing the hardness of annealed copper oxidization

Uniaxial test specimens were made of cold-rolled ASTM A1008 steel having a thickness of 2.94 mm. Tensile tests were conducted in a cruciform (biaxial) testing machine [6]. In this machine, the load is applied using hydraulic actuators, which are controlled in orthogonal pairs [6]. Each of these actuators has This study proposes a novel approach to surface strain measurement for cylindrical rock specimens subjected to uniaxial compression using distributed fibre optic sensing technology. The capability and accuracy of this approach in measuring the full-field strain distribution of a rock specimen have been verified by a series of uniaxial compressive .

As shown in Fig. 3. the stress–strain curve of rock under uniaxial compression shows four stages: compaction, elastic deformation, plastic deformation and post-peak brittle failure.In the compaction stage, the curve shows a concave shape, indicating that the internal pores and cracks of the rock are gradually sealed under compression, showing nonlinear .Compression tests are performed to characterize the behavior of a material under compressive loading.; During the test, pressure is applied to a specimen using compression platens or special tools mounted on a universal testing machine to determine various properties of the material being tested.; The test data delivers results in the form of a stress-strain diagram that .MECH 2120 Mechanics of Materials Laboratory Lab Assignment # 3: Uniaxial Compression Test of Aluminum cylindrical specimen Safety First! Ignoring Safety Precautions will be penalized. Aim: 1. Apply ASTM-E9 Standard on test specimens 2. .MECH 2120 Mechanics of Materials Laboratory Lab Assignment # 3: Uniaxial Compression Test of plastic cylindrical specimen Safety First! Ignoring Safety Precautions will be penalized. Aim: 1. Apply ASTM-D695 Standard on test specimens 2. Obtain reliable and duplicable data. 3.

This article discusses the characteristics of deformation during axial compression testing, including deformation modes, compressive properties, and compression-test deformation mechanics. It describes the procedures for the use of compression testing for the measurement of the deformation and fracture properties of materials. One of the parameters which affect the uniaxial compressive strength (UCS) of rock materials is the length to diameter ratio (L/D) of test cores. ASTM recommends a ratio of between 2 and 2.5, and ISRM suggests 2.5–3:1. Research has shown that high UCS values are obtained for L/D ratios <2, a very slight difference in values between 2 and 2.5, and they . Uniaxial compression of cylindrical specimen is a simple and practical method to investigate the mechanical behavior and microstructure evolution in metal plastic working. Friction at workpiece-tool interface is a critical factor affecting the compression behavior.

uniaxial compression testing machine

unconfined compression test procedure

web54K Followers, 1,232 Following, 3,757 Posts - See Instagram photos and videos from Luisa Fernanda (@luisitafernandainsta)

uniaxial compression test of plastic cylindrical specimen|unconfined compression test data sheet